LED lightbulbs are a new and exciting kind of LED that you may have seen at home or in the stores. They're nothing like the traditional lightbulbs everyone has been forced to use for years. In the old days, lightbulbs produced light by heating up a thin piece of wire until it reached an extremely hot temperature and began to give off illumination; with LED bulbs, however the bulb is created using individual parts called "light-emitting diodes" which more intelligently make them work together in order for your visible spectrum to essentially be illuminated. We will take a look at the key components of an LED bulb and how they interact to produce light in this article.

Driver - Another significant element of the LED bulb is a driver. It simply converts the type of electricity from your wall socket to that which is usable by an LED chip. The driver also manages the supply of power that goes to the LED chip so it receives just enough, voltage and current for proper functioning without overheating.

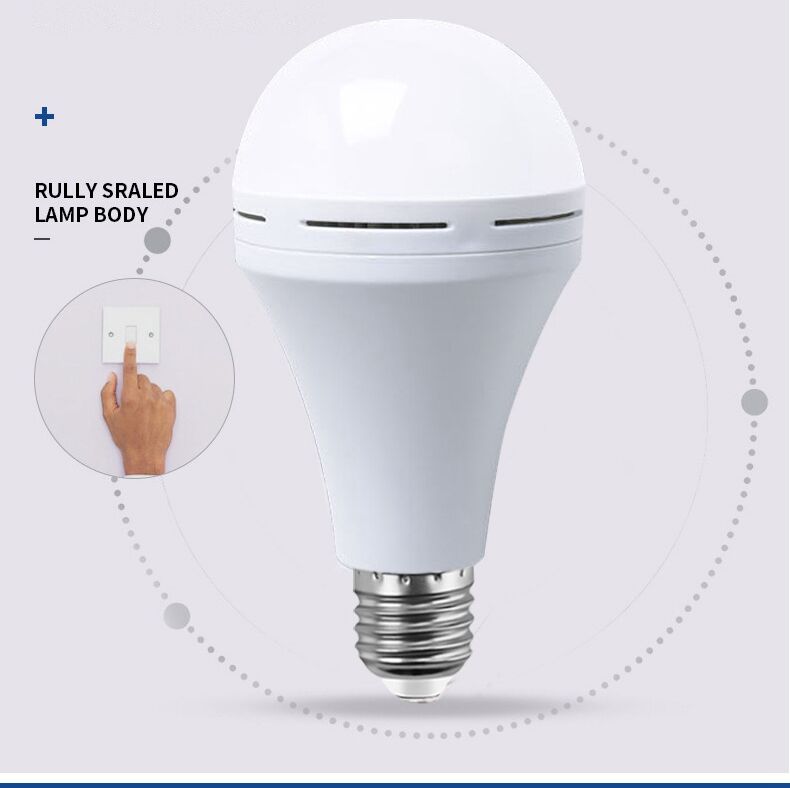

LED lens: The LED lens is the plastic cover over your LED bulb. It helps distribute light and protect it from dirt, road debris as well any off-road damage It is able to alter the way that light comes from a source, allowing for varied beam angles or even distribution of light. The lens provides additional protection for the LED chip from dust, moisture.

Heart of the LED bulb: The LED chip, owing to its function production abundance light and making it available. It consists of two materials types P-type and N-type semiconductors. While passing the electricity from P-type to Ntype material, it gives out energy in the form of light termed as photons. This is the process that enables LED chip to produce light which we observe.

Driver (most crucial, because this will help to power the LED chip) It converts the alternating current (AC) that runs through your wall socket into direct current (DC), with which the LED chip can work. The driver also controls power draw to and from the chip so it doesn't overheat or burn out.

Heat Sink : The heat sink is a necessary component that will keep the led chip cool. The heat sink pulls the excess heat from that LED chip and prevents it from overheating, as those chips produce lots of heat when they are on. It is typically aluminum, because metal has a super high capacity to get the heat out of the LED chip.

Lens: Among all the parts of an LED bulb, lens plays a crucial role in determining direction and quality of light emission. Other lenses might be able to provide other beam angles, or even spread light out a little more. The lens also serves as protection from dust, moisture and other environmental contaminants which could potentially harm the LED chip.

company's primary business involves manufacturing of LED products. current offerings comprise range of bulbs T bulb lights panels lights, led bulb parts lights, tubes with T5 and T8 lights, fan lights, and personalized design many more products.

In addition, more than 40 countries across Asia as well as including over 40 countries in Asia, Middle East, Africa, and Latin America, have established us as a trusted brand in the industry. products are a hit in over 40 countries throughout Asia as well as the Middle East, Africa, and Latin led bulb parts. primary customers are wholesalers, retailers as well as decoration firms and department stores. instance, bestselling products, like the A bulb T bulb have provided lighting services more than a million people worldwide.

Zhongshan Hulang Lighting Electrical Co., Ltd. is a manufacturer LED bulb panel lights. With over 15 years' experience in the production export of LED products worldwideOver 200 people work for company. have increased our production capacity by substantial amount have improved our after-sales service by implementing an improved structure.Equipped with 16 automatic production lines four warehouses that cover 28,000 led bulb parts meters We are capable of having a daily production capacity of around 200,000 units. We can effectively manage large orders and meet our customers' needs promptly.

company accredited with ISO9001, CE SGS RoHS CCC as well as other certifications. There are eight engineers at our disposal who are skilled in R D. They provide a single-source solution that ranges from customers' ideas speedy design samples, bulk order production, and distribution. employ most advanced testing equipment that guarantees 100 high-quality. They include aging test equipment and high-voltage shock testers. temperature and humidity chambers that are always use, including the sphere test machine many more.With our in-house SMT workshop, equipped with state of art automated led bulb parts imported from South Korea, achieve the capacity to produce daily up to 200,000 places.

Copyright © Zhongshan Hulang Lighting Electrical Co.,Ltd. All Rights Reserved - Privacy Policy